Silcarb comissioned a hybrid aluminum shaft melter at one of india's largest automative manufacturing facilites.

Read More...Twin crucible aluminum melting and holding furnace for gravity diecasting

Twin crucible aluminum melting and holding furnace for gravity diecasting with a centralized movable degassing unit achives high energy efficiency.

Read More...Silcarb Recrystallized bags top honours at the Economic Times MSME Awards 2025!

India’s only maker of SiC & MoSi₂ heaters—and pioneer of carbon‑fibre lines for strategic sectors of our country -has been recognised for its

Read More...Defence inspection before despatch

Defence inspection was conducted at the Silcarb plant before dispatch, ensuring quenching in less than 10 seconds from 1300°C. The required properties

Read More...Silcarb on its journey towards complete Carbon Neutrality

Silcarb, on its journey towards complete #CarbonNeutrality, is proud to be ISO certified with: ✅ ISO 45001 – Occupational Health & Safety ✅ ISO

Read More...High power output furnaces for IIT

Silcarb is currently commissioning two complex high power output furnaces for IIT where the purpose of the furnace is to simulate an explosion and

Read More...fixed hearth front loading furnace for 1450 degrees c

We’re excited to announce the commissioning of our Fixed Hearth Front Loading Furnace, designed to operate at 1450°C. Engineered for high efficiency

Read More...Nitride bonded and reaction bonded silicon carbide feed chambers

Nitride bonded and reaction bonded silicon carbide feed chambers and spigots for wear applications manufactured at our bangalore plant

Read More...gas fired tilting furnaces with electrically heated transfer ladels

Commissioned a battery of gas fired melters and electrically heated transfer ladels for a new diecasting plant in Bangalore

Read More...Handed over our third lab scale carbon fiber line

Handed over our third lab scale carbon fiber line...now moving onto manufacturing the next 30 tonne per annum line

Read More...1500 degrees c grooved hearth furnace

Shipped out a 1500 degrees c grooved hearth furnace with a complete automated loading system. The furnace has a +-3 degrees c temperature uniformity

Read More...Reaction bonded Sic

New batch of reaction bonded silicon carbide wear resistant spigot liners under despatch

Read More...1850 degrees c mosi2 heaters with hot and cold bent Le and Lu

1850 degrees c mosi2 heaters with hot and cold bent Le and Lu ready for despatch for the optical fibre industry

Read More...Silcarb Achieves Milestone with Fourth Carbon Fiber Heat Treatment Line Completion

Silcarb successfully completes its third carbon fiber heat treatment line. The company is now in the advanced stages of manufacturing a mid-sized

Read More...Breaking New Ground in Extreme Temperature Technology!

Silcarb is thrilled to announce the commissioning of our latest cutting-edge furnace, setting new benchmarks in high-temperature capabilities.

Read More...Energy project in Karnataka.

Silcarb doubles down on its commitment to #CarbonNeutrality with a brand new 1 MW wind energy project in Karnataka.

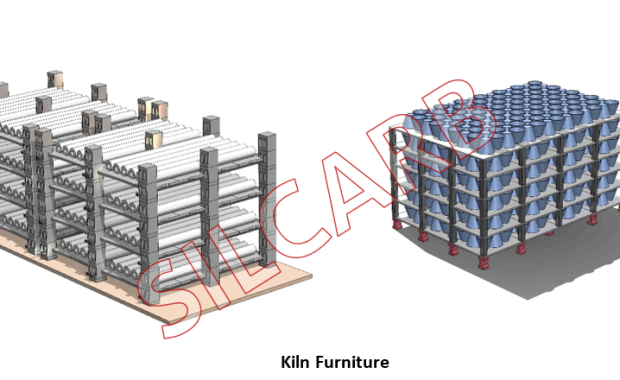

Read More...Kiln Car Engineering

SILCARB has a dedicated team for engineering our customer’s Kiln car requirements. Engineering based on in-depth knowledge of material (all of which

Read More...Burner Tubes

SILCARB manufactures a complete range of RBSiC/ SiSiC Burner tubes. Our NBSiC Burner tubes can be used upto a temperature of 1450 °C. We make

Read More...SILCARB commissions India’s first and only Carbon Fibre Line…

Carbon Fibre is of strategic importance to India. Silcarb along with the Indian National Aeronautics have Successfully Installed a complete Carbon

Read More...High pressure Autoclave

Silcarb built a high pressure Autoclave electrically heated upto 400 degrees c for Nuclear Fuel Cell production

Read More...New Design Shaft Furnace

A brand-new design shaft furnace has been shipped to a tier-1 Aluminium Die Caster with new age refractories. The current range of refractories being

Read More...Explosion Test Furnace

We built a furnace for IIT Gujrat, where we simulated a building catching fire, where the temperature reaches 1200 deg centigrade rapidly, under high

Read More...1750 Degree Centigrade Kiln

1750 Degree Centigrade Kiln under production at Silcarb. Refractory lining in house,mosi2 manufactured in house ,Fabrication of furnace in house,

Read More...Electric Shaft Melter

Completed successful installation of our first Electric Shaft Melter.As gas prices are going up, an existing customer of Silcarb wanted to run an

Read More...Ceramic Pump Seals made of RBSIC and SISIC.

Silcarb’s reaction bonded high density Silicon Carbide seal, with a mirror finish. Silcarb has installed a brand-new facility to manufacture pump

Read More...40 years of working with silicon carbide

Silcarb has been manufacturing high quality Silicon Carbide based Ceramics now for 40 years. We manufacture reaction bonded Silicon Carbide, Nitride

Read More...1650 Degrees Centigrade Electric Kiln

1650 Degrees Centigrade Electric Kiln with a SIC hearth under production at our plant. Furnace is used in manufacturing Alumina based technical

Read More...Downdraft shuttle kiln

1700 Degree centigrade downdraft shuttle kiln under production at Silcarb plant. The shuttle kiln is operating under a positive pressure in order to

Read More...Electrical shaft

An #electrical shaft #melting #furnace #aluminium #aluminum #diecasting #makeinindia #ceramics #furnaces #heaters #autoparts #refractory #engineering

Read More...1620 Degrees Centigrade Downdraft Shuttle Kiln

Completed building and “Fired’’ 1620 Degrees Centigrade Downdraft Shuttle Kiln today . This furnace uses new age burners with Recrystallized Burner

Read More...Rapid Aluminum Melting Furnace

Couple of rapid Melt Furnaces being shipped out of our plant. These are used to augment our main Melter at the same plate with shop return melts.

Read More...Installing 2 Megawatts of Solar Panels

Silcarb has started installing 2 Megawatts of Solar Panels for both Rooftop solar and Ground mounted solar in it’s commitment towards achieving carbon

Read More...Molten Metal Application for Ceramics

Entire range of molten metal contact application for the primary aluminium industry products are being manufactured and assembled at our plant in

Read More...Shaft Melter

We built a new age Shaft Melter Vacuum Furnace for 1700 degree. Switched on a Liquid Phase Reaction Vacuum Furnace for 1700 degree centigrade at our

Read More...Vacuum Furnace for 1700 degrees

Switched on a liquid phase reaction Vacuum Furnace for 1700 degrees c at our Bangalore plant today…exciting ceramics lay ahead !

Read More...Bulletproof Vest under production

Ultralight, ultra strong, ceramic bulletproof vest under production at our plant today! We have achieved threat level 3/4 with our ceramics of

Read More...20 Tonnes of oxide Bonded

20 Tonnes of Oxide Bonded Ceramics was completed for use in a porcelain insulator plant as kiln furniture.

Read More...16 tonne melter

A 16 tonne Melter being shipped out of our plant today. Electrically heated -1250 degree centigrade, Bright Annealing Furnace A 40 foot electrically

Read More...Electrically heated (1250 degrees c)bright annealing furnace

A 40 foot electrically heated (1250 degrees c)bright annealing furnace under production at our plant

Read More...Raiser Hearth

Raiser hearth 1700 deg c in operation at customer’s sight

Read More...Octagon Furnace

Completed A Crucible Melt Integral Holding Furnace for A Pressure Die Casting Plant in The South of India Aluminium Die Casting Aluminium Melting

Read More...Shaft Melting Furnace

New Design Aluminium Shaft Melting Furnace Working at Tier-1 Auto Plant with A Fuel Efficiency Of 50,000 KCAL Per Tonne

Read More...REVB Furnace

Finished a 12 tonne revb furnace in record time, which was installed and commissioned at our customers place this week. New design roof and door with

Read More...Gas Furnace

Built A 3m X 3m High Temperature Furnace to Test Explosions and Fire Resistance For Glass And Building Materials

Read More...Ultra Wide Span High-Temperature Furnace

A government of India company needed an ultra wide span high temperature furnace to sinter certain defence related superalloys. The operating

Read More...Double Door Muffle Furnace

Silcarb has just finished installing a sintering furnace for zircornia inserts. The furnace has a double door for ease of loading I.e loading and

Read More...Online Changing of SiC Heaters on a Silcarb Furnace

The Silcarb Aluminum/copper furnaces have a distinct advantage where the furnace heat is not lost while changing a failed heater. The crucible stays

Read More...Buhler Pressure Die-casting

Silcarb has a current population in excess of 1000 electric holding furnaces for pressure die casting. Many of these are operating on Buhler

Read More...Energy Efficient Electric Melting Furnace

Silcarb has installed an extremely energy efficient electric melting furnace for aluminum. This furnace works on zero pollution and is completely

Read More...Electric auto-charge melting furnace

Silcarb is manufacturing a brand new electric tower furnace with a new age refractory castable as the metal contact material. Typically most metal

Read More...